The law requires employers to prevent or control the exposure of employees and others (e.g. subcontractors) to hazardous substances at work.

Before using RPE, exposure should be controlled by other measures (such as local exhaust ventilation), which are reasonably practicable, however RPE is often used as part of the control measures in stone masonry operations

Fit Testing Basics

Introduction

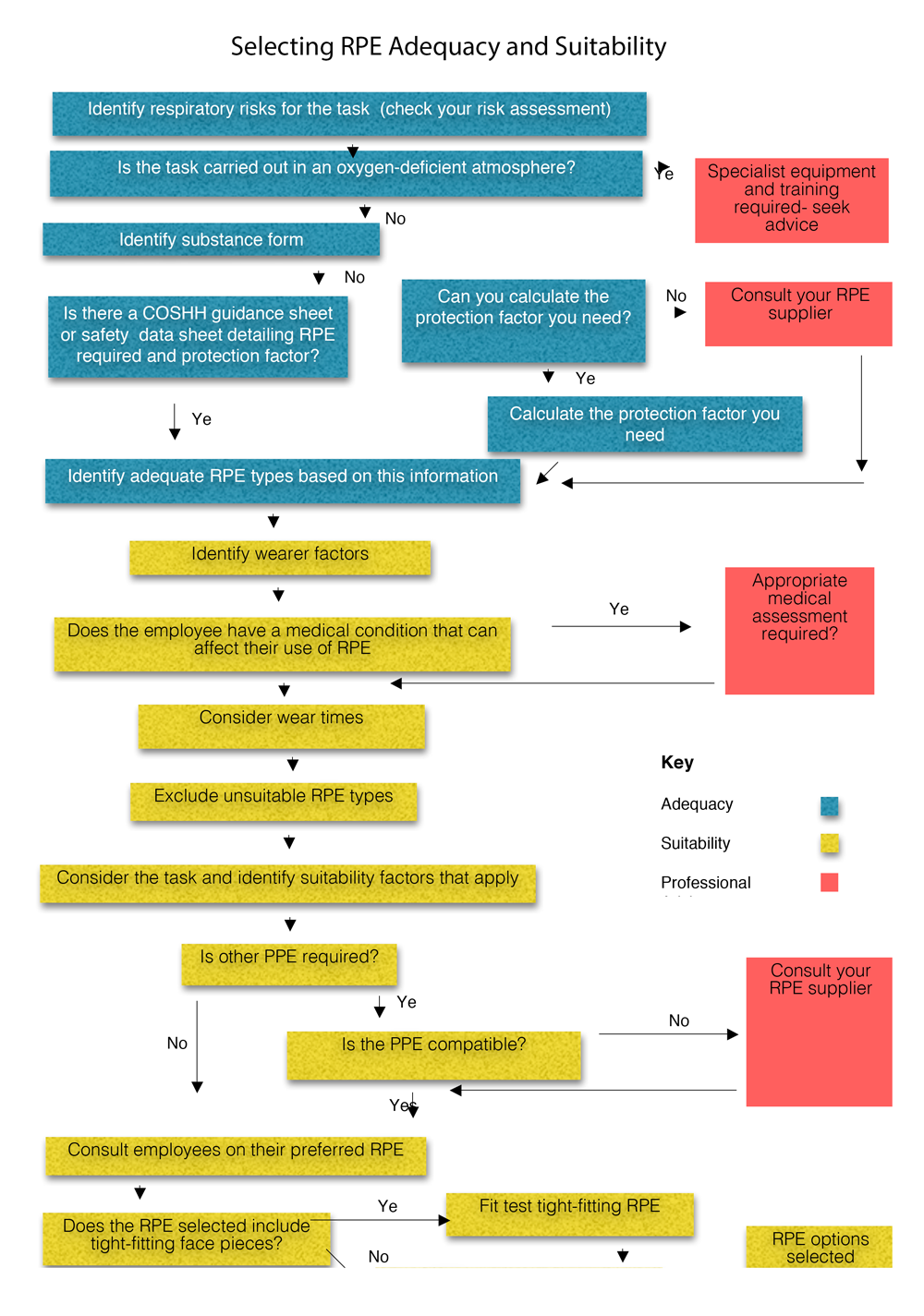

Where RPE is used, it must be able to provide adequate protection for individual wearers. RPE can’t protect the wearer if it leaks. A major cause of leaks is poor fit – tight-fitting facepieces need to fit the wearer’s face to be effective.

As people come in all sorts of shapes and sizes it is unlikely that one particular type or size of RPE facepiece will fit everyone. Fit testing will ensure that the equipment selected is suitable for the wearer.

Recent research indicates that up to 50% of all RPE used does not offer the wearer the level of protection assumed and one of the major reasons is that it simply does not fit! Yet, under the regulations RPE must be correctly selected and this includes, for many types of RPE, a face piece Fit Test conducted by a competent person.

What you need to do

The best time to do fit testing is at the initial selection stage, when individual users can be given a choice of adequate models of RPE. You should ensure that the make, model, type and size of facepiece that they wore when they had their successful fit test is made available for their use. If an employee wears more than one type of tight-fitting facepiece, then each type of facepiece should be fit tested.

How to do it

RPE fit testing should be conducted by a competent person – you should take steps to ensure that person who carries out the fit test is appropriately trained, qualified and experienced, and is provided with appropriate information to undertake each particular task. The British Safety Industry Federation (BSIF) has introduced a scheme for fit testers , which may provide evidence to help you decide whether a fit tester is competent. The Fit2Fit RPE Fit Test Providers Accreditation Scheme is designed to confirm the competency of any person performing face piece fit testing.

Facial hair

Many masks rely on a good seal against the face so that, when you breathe air in, it is drawn into the filter material where the air is cleaned. If there are any gaps around the edges of the mask, ‘dirty’ air will pass through these gaps and into your lungs. It is therefore very important that you put your mask on correctly and check for a good fit every time.

Facial hair – stubble and beards – make it impossible to get a good seal of the mask to the face.

If you are clean-shaven when wearing tight-fitting masks (ie those which rely on a good seal to the face), this will help prevent leakage of contaminated air around the edges of the mask and into your lungs. You will therefore be breathing in clean air, which will help you stay healthy.

If there are good reasons for having a beard (eg for religious reasons), alternative forms of RPE, that do not rely on a tight fit to the face, are available.

Useful Documents